The BTG-8 Photovoltaic Glass Spectral Transmittance Tester is designed and manufactured by Qinhuangdao Xianhe Technology Development Co., Ltd. for testing the transmittance of solar photovoltaic glass. It is also suitable for float glass, insulated glass, tempered glass, laminated glass, and coating. Testing of light transmittance of glass, car glass, etc.

This instrument consists of a workbench, spectrometer and control computer. The workbench size is 2000*1300mm. The height of the workbench is 800mm. The surface of the work surface is covered with felt to allow the glass to slide on it.

System characteristics

1. Resistant to ambient light interference and can work continuously for a long time.

2. It adopts industrial computer control and has good scalability and stability.

3. The core components of the system have high stability and durability.

4. The system test software is user-friendly and has a sound prompt function, test path guidance during automatic testing, and arbitrarily edit the waiting interval of each point during testing.

5. The test results are automatically stored, and the query, retrieval, statistics and report printing functions of the test results are highly integrated and convenient to use.

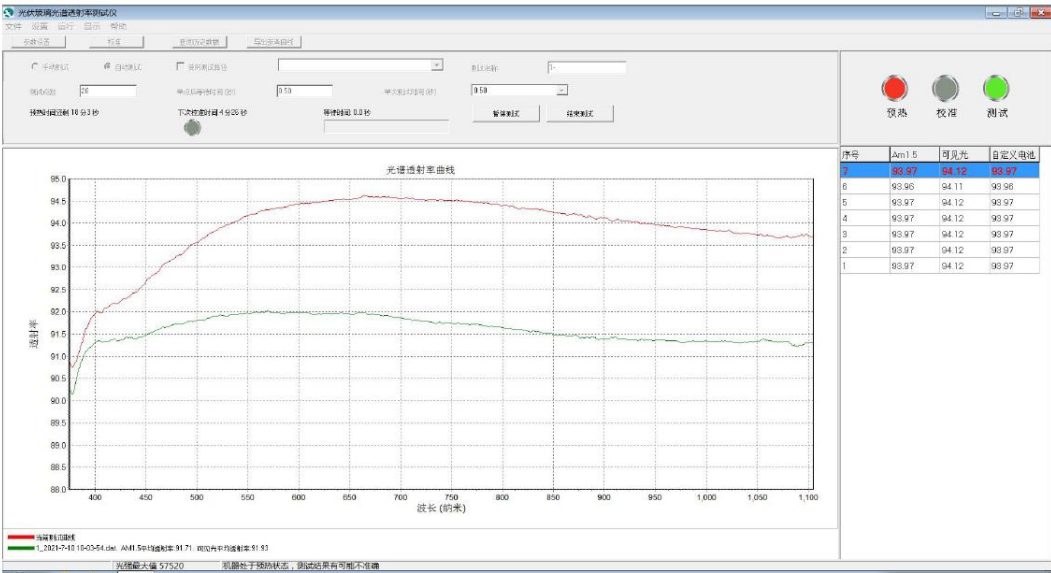

7. Multiple curves can be superimposed and displayed for test curve comparison, and a difference curve for comparison of two curves can be provided.

8. All test results are saved in the database, and the data can be retrieved and exported to EXCEL files according to conditions.

9. All test results are saved in the database, and the data can be retrieved and exported to EXCEL files according to conditions.

10. Database data can be exported and backed up for permanent storage.

11. Fault alarm function: When a hardware failure occurs, there will be a fault information indication on the screen status bar or pop-up window, and the fault information will be stored in the database for analysis.

12. Resistant to ambient light interference.

13. Can run continuously for a long time.

Equipment functions

1. It can output the spectral transmittance value from 380 to 1100nm and display the spectral transmittance curve.

2. The system uses the AM1.5 standard solar spectrum and the D65 light source spectral distribution. It can automatically calculate the AM1.5 effective integrated transmittance, the D65 light source visible light transmittance and the effective transmittance calculated based on the user-defined battery response curve. It can also be calculated according to the customer's requirements. Transmittance values under other standard light source conditions are required.

3. It can measure the color (L*a*b*) value and color difference of the sample.

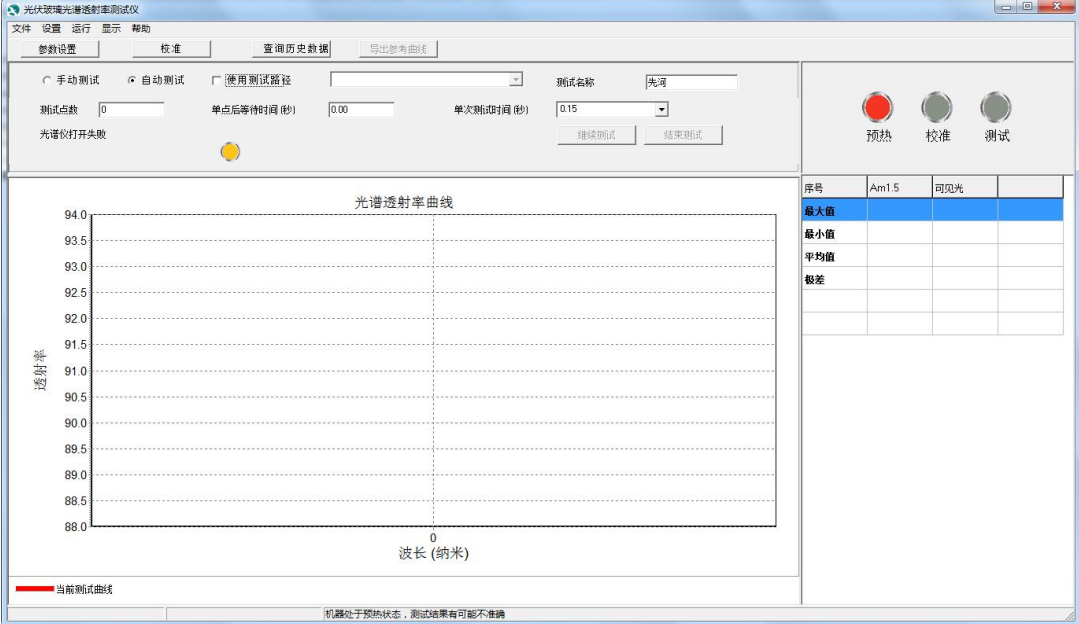

4. The test process has sound reminders and indicator light reminders. The system emits a "beep" sound before the test and a "beep" sound after the test is completed to remind the customer not to move the sample during the test process. At the same time, the system interface has an indicator light to display the machine. working status.

5. It has automatic calibration function, the calibration cycle can be set by yourself, and the remaining time for the next calibration is displayed in real time.

6. It has three working modes: manual testing, automatic testing and path testing.

6.1 Manual test mode: After setting the test time, test interval, number of tests and other parameters, push the glass into the test area and manually click to start the test. After completing the test, click Save Results to save the test data.

6.2 Automatic test mode: After setting the test parameters, push the glass into the test area and the machine will automatically start testing.

After the test is completed, the results are automatically stored in the database.

6.3 Path test mode: Edit the number, location, test sequence, and time interval of movement between each test point in advance. After the sample is pushed into the test area, the screen prompts the next measurement point according to the planned test path. The measurement path of the test results is automatically saved at the end of the test.

Performance indicators

1. Wavelength range: 380-1100nm

2. Spectral half-maximum width: 4.3nm

3. Wavelength accuracy: 0.2-0.3nm

4. Spectral wavelength interval: ≤1nm

5. Data storage interval: 1nm, data calculation interval: 5nm

6. Measurement speed: The fastest speed for each point and each measurement is 150ms

7. Measuring range: 0~100%

8. Measurement accuracy: 0.01%

9. Measurement stability: ≤0.05%

10. Measurement repeatability: ≤0.05%

11. Measurement size: maximum 2400mm×1300mm, minimum 80mm×80mm

12. Measurement geometric conditions: integrating sphere illumination, quasi-direct collection

13. Integrating sphere diameter: 120mm

14. Light source specifications: single light source 12V20W

15. Light source bulb life: 4000 hours

16. Work surface size: 2000mm*1300mm

17. Monitor: 31.5 inches

18. Overall machine size: 2000mm*1460mm*1100mm (length*width*height)

5. Usage environment

1. Ambient temperature: 0℃~40℃

2. Environmental humidity: <98%

3. Power supply mode: AC 220V

4. Avoid vibration